Forward-looking analyses increase mining efficiency in the extraction of potash as a raw material and optimize underground mapping.

Benefits for the raw materials industry:

Potash and salt are vital minerals for nutrition as well as being important raw materials for numerous industrial applications.

The K+S Group helps farmers to secure global food supplies, offers solutions that keep industries running, enriches the daily life of consumers and ensures safety in winter. When extracting raw materials underground, it is important to mine the deposits as precisely as possible in order to optimize the resources. Geological composition, geographical location and thickness of the deposits are all taken into account.

K+S extracts potassium, magnesium and sulphur-containing potash salts in six mines in Germany. At the Zielitz potash plant in Saxony-Anhalt, the largest single K+S site, the company produces 12 million tonnes of crude potash salts per year. Numerous geological challenges must be assessed in the extraction process:

Only on the basis of detailed answers to these challenges can the company effectively extract the valuable potash salt. For this purpose, K+S uses, among other methods, borehole surveys. The aim of the drillings is to penetrate the sylvinite potash salt rock and to determine the extent of the potash bed. With the help of geophysical measuring methods, the spatial environment can be interpolated and three-dimensional images can be created of the rock structure surrounding the borehole.

Castalytics GmbH supports K+S with its experience in Big Data and Predictive Analytics. The systems developed by Castalytics combine predictive analytics with artificial intelligence based on big data to optimize forecasts.

The technology enables the processing and use of large amounts of data in short periods of time and continuously analyzes the available data using self-learning algorithms. The system detects recurring patterns and ensures high forecast accuracy thanks to the algorithms. On the basis of this technology, K+S and Castalytics GmbH have developed a resource optimization system together.

This software solution uses a digital, geological 3D model supplied by K+S. Geographical, geological and geotechnical data flow into this database. The resource optimization tool uses this 3D model to calculate the optimum mining corridor at the Zielitz site. For 3D modelling, georadar measurements are used as a database to test drillings.

Elementary information in the model includes: position, distribution, depth and the geological structure and course of the rock. In this way, for example, the upper and lower edges to the sylvinite or the lower edge to the anhydrite can be determined. The course of the most productive seam can be modelled and its excavation planned.

The analysis system evaluates the specified mining parameters as well as safety and quality-relevant features. As the application progresses, it refines its calculations and learns with the help of algorithms. Based on the combination of past experience and current findings, the system calculates three-dimensional solid shapes representing the optimized mining corridor in the potash seam.

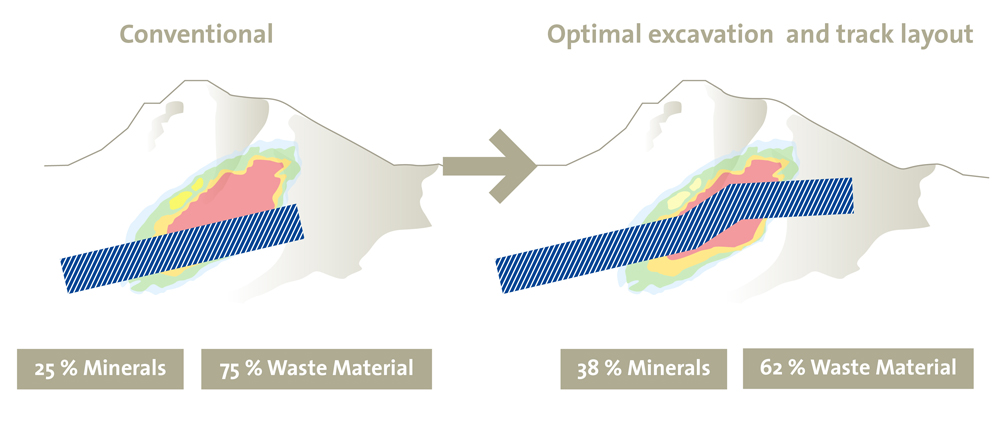

The analysis technology from Castalytics makes it possible to plan the mining of potash in underground deposits as precisely as possible. The deposit can be mined optimally, so that on the one hand maximum potash is extracted and on the other hand the transport of secondary rock is reduced.

For a detailed understanding of deposits, the three-dimensional model can not only include the data of geological modelling of the potash deposit in the calculations, but also current knowledge gained at short notice.

This information can be processed further in order to suggest a mining plan that is as precise as possible.

Castalytics’ new digitisation solution thus supports the calculation and optimal choice of mining and mapping in the potash seam.

Customer K+S

K+S sees itself as a customer-focused, independent supplier of mineral products for the agriculture, industry, consumer and communities’ sectors and aims to increase EBITDA to ₠ 3 billion by 2030.

Our more than 14,000 employees help farmers secure the world’s food supply, provide solutions that keep industries running, enrich consumers’ daily lives and ensure safety in the winter.

We serve the steadily increasing demand for mineral products from production facilities in Europe, North and South America and operate a worldwide sales network.

We strive for sustainability because we are committed to our responsibility towards people, the environment, communities and the economy in the regions in which we operate. www.k-plus-s.com